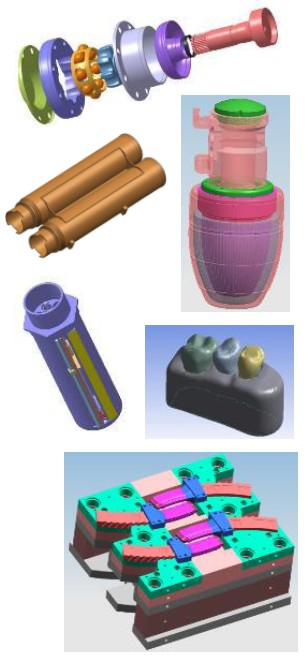

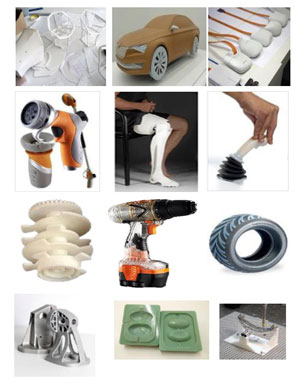

Suitable for 20 no's sample size for simple plastic and rubber parts.

Wax moulding parts for casting.

| SL. NO. | MATERIALS OR PRODUCT TESTED | TYPE OF TEST | TEST METHOD SPECIFICATION |

|---|---|---|---|

| 01 | Fibre reinforced composites | Glass Fibre content / Double Lap shear / Fiber Areal Weight / Fire Retardancy / Ignition Loss / Lap Shear / Short beam Shear / Tension - Tension fatigue / Void Content / Volatile content / | IS 14856 / ASTM D 3528 / ASTM D 3776 / IS 14856 / ASTM D 2584 / ASTM D 3164 / ASTM D 2344 / ASTM D 3479 / ASTM D 2734 / ASTM D 3530 / |

| 02 | Plastic Materials and Products | Ash content / Chemical resistance / Water absorption / Shore A hardness, Shore D / Vibration / Flexural fatigue / fatigue Resistance (S-N) curve / Flammability (rate of burning) / Uniaxial fatigue / Density | ASTM D 5630 / ASTM D 543 / ASTM D 570 / ASTM D 2240 / ISO 2247 / ASTM D 7774 / ASTM E 739 / ASTM D 635 / ASTM D 7791 / ASTM D 792 / |

| 03 | Sandwiched Composite Materials | Water Absorption / Density of Core Materials / Compression strength / Shear Strength / Tensile strength | ASTM C 272 / ASTM C 271 / ASTM C 365 / ASTM C 393 / ASTM C 297 / |

| 04 | Acrylic Bone cement | Controlled fatigue test | ASTM F 2118 / |

| 05 | Baloon stents | Three point bending test | ASTM F 2606 / |

| 06 | Bone screw | Axial Pull Strength, Breaking Angle, Dimension, Maximum Torque, Torsional Yield Strength / | ASTM F 543 / |

| 07 | Containers | Vibration Test / | ASTM D 999 / |

| 08 | Foam | Compression set, Density | IS 7888 |

| 09 | Medical Implants | Cyclic Fatigue Testing for Knee Joints / Cyclic Fatigue Testing for Knee Joints / | ASTM F 1800 / ASTM F 3140 / |

| 10 | Plastic smart cards | Dynamic Torsion test, Dimension of cards, Dynamic Bending test, Warpage. | ISO 10373-1 |

| 11 | Rubber | Compression set / Cyclic fatigue / Wear resistance / | ASTM D 395 / ASTM D 4482 / ASTM G 99 / |

| 12 | Stents | Dimension Measurements | ISO 25539-2 |